Skill shortage: been here before!

There’s been talk about a current and pending shortages of welders in Australia lately.

Research found the issue had occurred before and what was done to solve it.

The following is a summary of that research.

Skill shortages within manufacturing are not new. World War II created a similar problem.

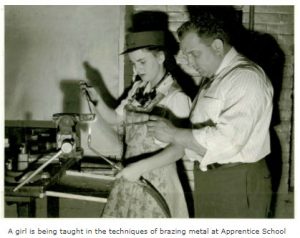

The shortage was resolved through the training and employment of women.

The  initiative then, Training Within Industry (TWI), it comprised of:

initiative then, Training Within Industry (TWI), it comprised of:

- Task capability aptitude tests applied before skills training.

- Manufactures using training programs on single skill disciplines.

- Current manufacturing staff upskilled as multi skilled supervisors and trainers.

- Governments funding technical institutions to hire manufacturing specialist trainers.

Today total world conflicts are not present, but fighting for commercial survival is and so are skill shortages. Revisit TWI as a way to overcome manufacturing skill problems and replicate the initiative using today’s tools. More can be done with less.

TWI solves welder shortage

Aptitude testing is available in the welding space to determine who would be good at it.

Manufactures can define tasks into single skill disciplines.

Use IoT to pass on skills to trainees without physical supervision is the big advantage.

Plus Governments and industry associations offer funding for guidance and help.

Today’s challenge; get the skills you need while maintaining commercial viability.

Find the trees within the forest of busyness.

Nothing good is made without some elbow grease involved.

Get Open Welding to help you.